Language EnglishРусский язык

加入收藏在線留言網(wǎng)站地圖歡迎光臨山東勝沃塑料機械科技有限公司官網(wǎng)!咨詢熱線

400-008-1116

400-008-1116

特點介紹:

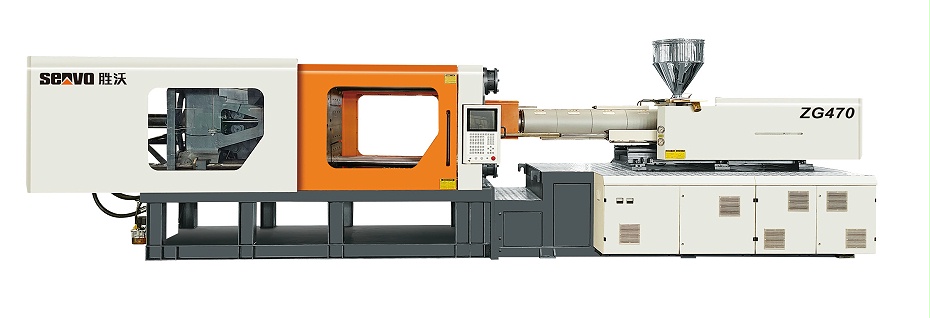

1、標(biāo)配雙合金螺桿料筒,更加耐磨、耐腐蝕,提高使用壽命,主要適配回料生產(chǎn)。

Double alloy screw barrel is standard,which is more wear-resistant and corrosion-resistant.

improves service life.and is mainlysuitable for recycling production.

2、標(biāo)配數(shù)控背壓閥。加大的動力系統(tǒng),射膠速度更快,縮短成產(chǎn)周期,提高生產(chǎn)效率。

Numerical control backpressure valve is standard. Enlarging the power system,

the injection speed is faster.the productioncycle is shortened,and the production efficiency is improved.

3、全新剛性機架,減震更加明顯,生產(chǎn)更穩(wěn)定。

New rigid frame.more obvious shock absorption and more stable production.

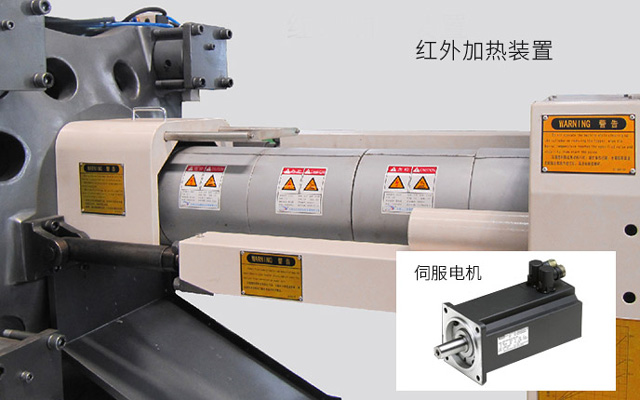

4、加熱可選配納米紅外節(jié)能加熱裝置,能量損失小、加熱質(zhì)量高。

Nano infrared energy-saving heating device can be selected for heating,with small energy loss and high heating quality.

| 技術(shù)參數(shù) SPECIFICATION |

ZG380/IU2800 |

ZG480/IU4000 |

ZG530/IU4400 |

ZG530S/IU6200 |

ZG600/IU6200 |

ZG650/IU6200 |

|||||||

| 注射部份 INJECTION UNIT |

B |

B |

B |

B |

B |

B |

|||||||

| 注射容積 Shot Weight | cm3 | 2270 | 3261 | 3613 | 4942 | 4942 | 4942 | ||||||

| 注射量(PP回料)Injection Weight | g | 2430 | 3488 | 3866 | 5288 | 5288 | 5288 | ||||||

|

螺桿直徑 Screw Diameter |

mm | 85 | 95 | 100 | 110 | 110 | 110 | ||||||

| 螺桿長徑比 Screw L/D Ratio |

Sc |

19 | 19 | 19 | 19 | 19 | 19 | ||||||

| 對空注射速率 Injection Rate | cm3/s | 595 | 877 | 958 | 1055 | 1055 | 1055 | ||||||

| 注射壓力 Injection Pressure | Mpa | 122 | 122 | 122 | 126 | 126 | 126 | ||||||

| 最大塑化能力(PP回料) Plasticzation Capacity | g/s | 135 | 185 | 210 | 275 | 275 | 275 | ||||||

| 最大螺桿轉(zhuǎn)速 Max Screw Speed | rpm | 180(240) | 172(220) | 172(220) | 170(170) | 170(170) | 170(170) | ||||||

| 合模部份 CLAMPING UNIT |

|

|

|

|

|

|

|

||||||

| 合模力 Clamping Force | Kn | 3800 | 4800 | 5300 | 5300 | 6000 | 6500 | ||||||

| 最大移模行程 Clamping Stroke | mm | 700 | 780 | 850 | 850 | 900 | 950 | ||||||

| 拉桿內(nèi)間距 SpaceBetween Tie Bar(WxH) | mm | 730*710 | 820*780 | 860*820 | 860*820 | 920*880 | 960*920 | ||||||

| 最大模板距離 Max. Daylight | mm | 1450 | 1580 | 1750 | 1750 | 1800 | 1950 | ||||||

| 最大容模厚度 Max. Mold Height | mm | 750 | 800 | 900 | 900 | 900 | 1000 | ||||||

| 最小容模厚度 Min. Mold Height | mm | 250 | 280 | 320 | 320 | 320 | 350 | ||||||

| 頂出行程 Ejector Stroke | mm | 180 | 220 | 220 | 220 | 260 | 260 | ||||||

| 最大頂出推力 Ejector Force | Kn | 125 | 152 | 152 | 152 | 182 | 182 | ||||||

| 電控部份 CONTROL UNIT |

|

|

|

|

|

|

|

||||||

|

系統(tǒng)壓力 Pump Motor Power |

Mpa | 17.5 | 17.5 | 17.5 | 17.5 | 17.5 | 17.5 | ||||||

| 油泵電機功率 Heater Power | Kw | 50 | 40+37 | 50+37 |

65+31 |

65+31 | 65+31 | ||||||

|

油泵電機+儲料電機功率(選配)Pump Motor Power+Powerof storage motor (optional) |

Kw |

50+50 (一體式直驅(qū)) |

65+55 (一體式直驅(qū)) |

75+55 (一體式直驅(qū)) |

55+37+65 (一體式直驅(qū)) |

55+37+65 (一體式直驅(qū)) |

55+37+65 (一體式直驅(qū)) |

||||||

|

電熱功率 No.of Heater Control Zone |

Kw | 30 | 40 | 40 | 55 | 55 | 55 | ||||||

| 溫度控制 No.of Heater Control Zone | zone | 5 | 6 | 6 | 6 | 6 | 6 | ||||||

| 其他 OTHERS |

|

|

|

|

|

|

|

||||||

| 油箱容量 Oil Tank Capacity | L | 460 | 700 | 700 | 800 | 800 | 800 | ||||||

| 重量(約) Machine Weight | T | 14 | 18 | 21 | 21.5 | 24 | 28 | ||||||

| 外型尺 Machine Dimension (LxWxH) | M |

7x1.8x2.4 |

8x1.9x2.4 |

8.6x2x2.4 |

9.2x2x2.4 |

9.7x2.1x2.4 |

10x2.2x2.4 |

||||||

本網(wǎng)站所有技術(shù)參數(shù)僅供參考,本公司保留修改技術(shù)參數(shù)的權(quán)利,恕不另行通知。All technical parameters of this website are for reference only. The company reserves the right to modify the technical parameters without notice.

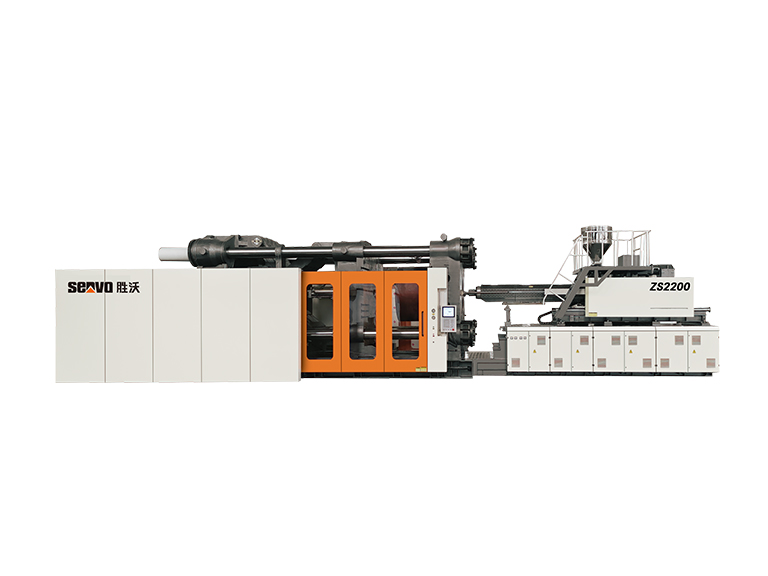

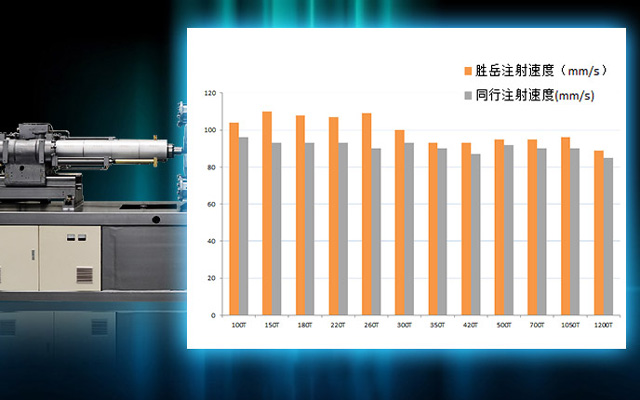

高排量的液壓系統(tǒng)設(shè)計,動力系統(tǒng)加大,注射速度比同類型產(chǎn)品提高15%,模循環(huán)周期縮短10-15%,全面提升注塑機表現(xiàn),可滿足高標(biāo)準(zhǔn)的成型要求

油路板分布在各執(zhí)行元件位置,響應(yīng)速度快,動態(tài)性能好,注塑過程更快速,產(chǎn)品成型更好

注射單元采用模組化的托板座設(shè)計,一線式雙缸平衡注射裝置,使螺桿在注塑過程中受力均勻,顯著提高射膠穩(wěn)定性,使料筒定位更加準(zhǔn)確

高剛性的寬模板設(shè)計,配合高安全系數(shù)的拉桿,整體提升合模結(jié)構(gòu)的剛性及穩(wěn)定性

伺服驅(qū)動器在鎖模保壓冷卻等階段能輸出最大壓力但保持速度接近零速,因而功率消耗小,更節(jié)能

料筒采用納米遠(yuǎn)紅外高效節(jié)能加熱裝置,改善了傳統(tǒng)加熱圈電熱轉(zhuǎn)換效率低、熱傳導(dǎo)率低、表面溫度高“兩低一高”缺點,比傳統(tǒng)加熱圈節(jié)能30%-40%

控制面板采用彩色屏幕,實時監(jiān)測生產(chǎn)進(jìn)程,并顯示各種故障診斷,操作更省心

人性化工藝參數(shù)設(shè)置,設(shè)置急停開關(guān),動作全面監(jiān)控,保護(hù)工作人員人身安全