Language EnglishРусский язык

加入收藏在線留言網(wǎng)站地圖歡迎光臨山東勝沃塑料機械科技有限公司官網(wǎng)!

咨詢熱線

400-008-1116

400-008-1116

特點介紹:

1、全電動射臺在保證高射速的同時,注射精度及動作響應速度均比油壓機成倍數(shù)級提升,機器生產(chǎn)穩(wěn)定性大幅度提升,并且產(chǎn)品克重精度高。

While ensuring high firing rate, the all-electric shootingplatform improves the injection accuracy and actionresponse speed by multiple times compared with thehydraulic press, which greatly improves the productionstability of the machine and has high product weightaccuracy。

2、油電組合方式相比傳統(tǒng)的雙油泵方式節(jié)能優(yōu)勢明顯,并且可以選擇開儲同步動作使用,進一步減少模生產(chǎn)周期,實現(xiàn)高產(chǎn)出低能耗,產(chǎn)品工藝與模生產(chǎn)周期相同的情況下能耗節(jié)約25-35%。

Compared with the traditional double oil pump mode,the oil-electricity combination mode has obviousenergy-saving advantages, and it can be used bysynchronous operation of opening and storing, furtherreducing the mold production cycle, realizing highoutput and low energy consumption, and saving energyconsumption by 25-35% under the condition that theproduct technology is the same as the mold productioncycle。

3、大排量油泵系統(tǒng)生產(chǎn)中始終處于高速高壓狀態(tài),零部件疲勞度及故障率高,油電混合機器的液壓系統(tǒng)生產(chǎn)中使用標準機的壓力速度,機器使用壽命延長故障率低。

The production of large displacement oil pump systemis always in a state of high speed and high pressure,and the fatigue and failure rate of parts are high. Thepressure speed of standard machine is used in theproduction of hydraulic system of oil-electric hybridmachine, so the service life of the machine is prolongedand the failure rate is low。

| 技術(shù)參數(shù)表 SPECIFICATION | IU400 | IU760 | |||||||||||||||||||||||||||||

| 注射部分 INJECTION UNIT | A | B | C | A | B | C | |||||||||||||||||||||||||

| 注射容積 Shot Weight |

cm3 |

166 | 212 | 276 | 333 | 416 | 530 | ||||||||||||||||||||||||

| 注射量(PS) Injection Weight | g | 151 | 193 | 252 | 303 | 380 | 482 | ||||||||||||||||||||||||

| 螺桿直徑 Screw Diameter | mm | 31 | 35 | 40 | 42 | 47 | 53 | ||||||||||||||||||||||||

| 螺桿長徑比 Screw L/D Ratio | Sc | 28:1 | 25:1 | 22:1 | 27:1 | 24:1 | 22:1 | ||||||||||||||||||||||||

| 對空注射速率 Injection Rate | cm3/s | 264 | 337 | 439 | 485 | 607 | 773 | ||||||||||||||||||||||||

| 最大注射壓力 Maximum injection pressure |

Mpa |

235 | 185 | 141 | 230 | 183 | 144 | ||||||||||||||||||||||||

| 最大保壓壓力 Maximum holding pressure | Mpa | 188 | 147 | 113 | 185 | 146 | 115 | ||||||||||||||||||||||||

| 最大塑化能力(PS) Plasticzation Capacity | g/s | 17 | 25 | 31 | 35 | 48 | 66 | ||||||||||||||||||||||||

| 注射行程 Injection Stroke | mm | 220 | 240 | ||||||||||||||||||||||||||||

| 最大螺桿轉(zhuǎn)速 Max Screw Speed | rpm | 400 | 400 | ||||||||||||||||||||||||||||

| 注射最大速度 Injection Speed | mm/s | 350 | 350 | ||||||||||||||||||||||||||||

| 注射+儲料電機功率 Injection and storage motor power | Kw | 34+15 | 47+26 | ||||||||||||||||||||||||||||

| 電熱功率 Heater Power | Kw | 15 | 22 | ||||||||||||||||||||||||||||

| 溫度控制區(qū)數(shù) No.of Heater Control Zone | zone | 5 | 5 | ||||||||||||||||||||||||||||

| 合模部分 CLAMPING UNIT |

|

|

|

HS220 |

|

|

|

|

HS260 |

|

|

|

|

HS320 |

|

|

|

|

HS400 |

|

|

|

|

HS450 |

|

|

|||||

| 合模力 Clamping Force | Kn | 2200 | 2600 | 3200 | 4000 | 4500 | |||||||||||||||||||||||||

| 最大移模行程 Clamping Stroke | mm | 500 | 550 | 640 | 730 | 780 | |||||||||||||||||||||||||

| 拉桿內(nèi)間距 SpaceBetweenTie Bar(WxH) | mm | 540*530 | 610*570 | 680*680 | 760*730 | 810*770 | |||||||||||||||||||||||||

| 最大模板距離 Max. Daylight | mm | 1050 | 1180 | 1320 | 1530 | 1580 | |||||||||||||||||||||||||

| 容模厚度(最小-最大) MaxMold Height ( Min-Max) | mm | 160-550 | 180-630 | 220-680 | 280-800 | 280-800 | |||||||||||||||||||||||||

| 頂出行程 Ejector Stroke | mm | 140 | 160 | 180 | 200 | 220 | |||||||||||||||||||||||||

| 最大頂出推力 Ejector Force | Kn | 68 |

99 |

125 | 138 | 152 | |||||||||||||||||||||||||

| 系統(tǒng)壓力 System Pressure | Kw | 17.5 | 17.5 | 17.5 | 17.5 | 17.5 | |||||||||||||||||||||||||

| 油泵電機功率 Pump Motor Power |

Kw |

31 | 35 | 43 | 60 | 65 | |||||||||||||||||||||||||

| 其他 OTHERS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 油箱容量 Oil Tank Capacity | L | 300 | 350 | 400 | 530 | 550 | |||||||||||||||||||||||||

| 理論重量 Machine Weight | T | 7 | 9 | 12.5 |

15.5 |

18 | |||||||||||||||||||||||||

| 外型尺寸 Machine Dimension (LxWxH) | M | 6x1.45x2 | 6.3x1.56x2.2 | 6.6x1.63x2.3 | 7.2x1.75x2.4 | 7.8x2x2.3 | |||||||||||||||||||||||||

本網(wǎng)站所有技術(shù)參數(shù)僅供參考,本公司保留修改技術(shù)參數(shù)的權(quán)利,恕不另行通知。All technical parameters of this website are for reference only. The company reserves the right to modify the technical parameters without notice.

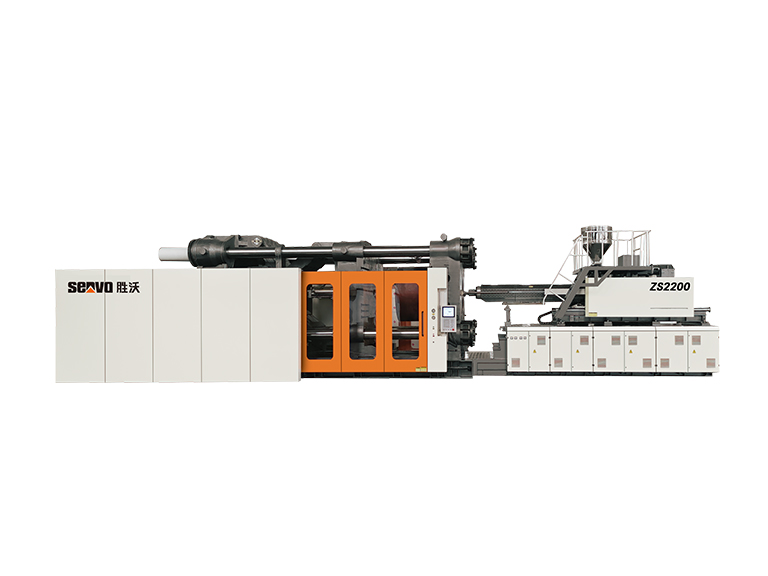

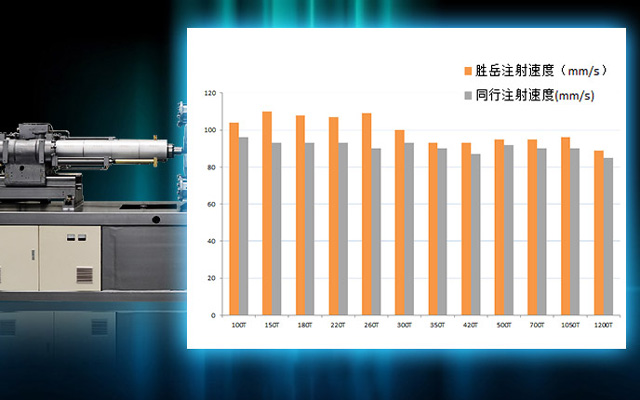

高排量的液壓系統(tǒng)設(shè)計,動力系統(tǒng)加大,注射速度比同類型產(chǎn)品提高15%,模循環(huán)周期縮短10-15%,全面提升注塑機表現(xiàn),可滿足高標準的成型要求

油路板分布在各執(zhí)行元件位置,響應速度快,動態(tài)性能好,注塑過程更快速,產(chǎn)品成型更好

注射單元采用模組化的托板座設(shè)計,一線式雙缸平衡注射裝置,使螺桿在注塑過程中受力均勻,顯著提高射膠穩(wěn)定性,使料筒定位更加準確

高剛性的寬模板設(shè)計,配合高安全系數(shù)的拉桿,整體提升合模結(jié)構(gòu)的剛性及穩(wěn)定性

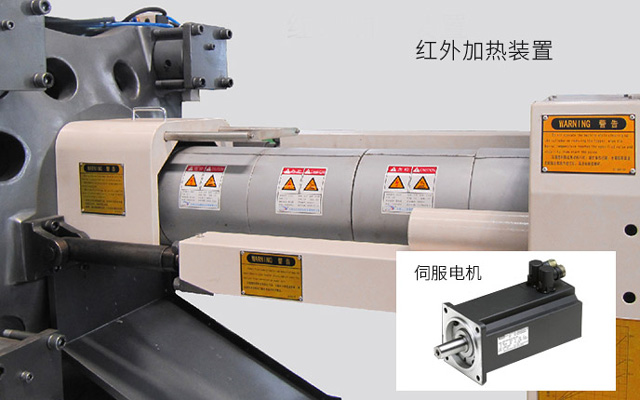

伺服驅(qū)動器在鎖模保壓冷卻等階段能輸出最大壓力但保持速度接近零速,因而功率消耗小,更節(jié)能

料筒采用納米遠紅外高效節(jié)能加熱裝置,改善了傳統(tǒng)加熱圈電熱轉(zhuǎn)換效率低、熱傳導率低、表面溫度高“兩低一高”缺點,比傳統(tǒng)加熱圈節(jié)能30%-40%

控制面板采用彩色屏幕,實時監(jiān)測生產(chǎn)進程,并顯示各種故障診斷,操作更省心

人性化工藝參數(shù)設(shè)置,設(shè)置急停開關(guān),動作全面監(jiān)控,保護工作人員人身安全